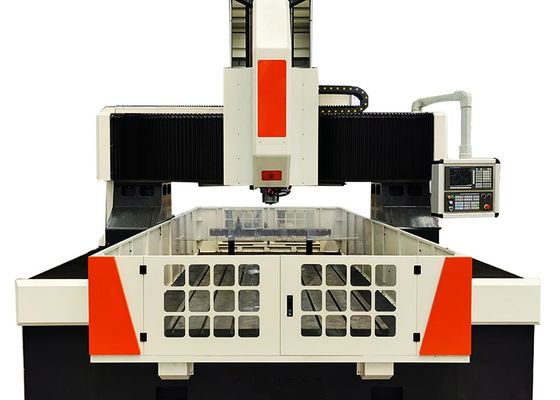

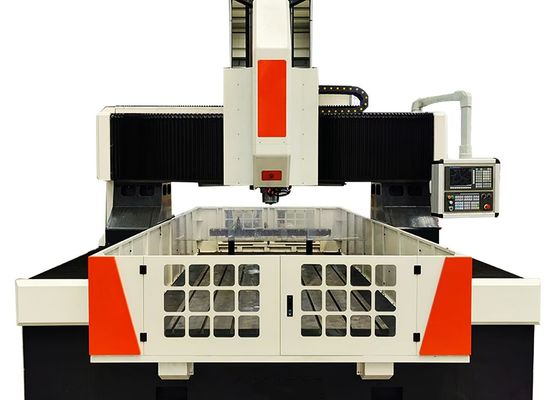

M3-M24mm Tapping Diameter CNC Gantry Flange Drill Mark Machine 1200mm Max.Horizontal Stroke

Application:

This equipment is specially engineered to perform drilling, chamfering, tapping, and milling processes on plate-type components and structural parts. It is primarily applied to the high-efficiency drilling of workpieces such as flanges, discs, rings, and plates—on the condition that the thickness of these workpieces falls within the effective processing range. The equipment is capable of drilling both through holes and blind holes in single-material components as well as composite materials.

Specifications:

| Workpiece size |

LxW |

1200x1200 mm |

| |

Gantry height |

600 mm |

| workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT50-150 |

| Max.drilling diamter |

Φ50 mm |

| Max.thickness |

≤180 mm |

| Tapping diameter |

M3-M24 mm |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

11kW |

| Distance from the lower end of the spindle to the worktable |

200-600mm |

|

Lateral movement of power head

(X axis)

|

Max.horizontal stroke |

1200 mm |

| Lateral movement speed |

0~8 r/min |

| Servo motor power for lateral movement |

1x2.4 kW |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke |

1200 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power |

2x2.4 kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

400 mm |

| Moving speed |

0~8 m/min |

| Servo motor power |

1x2.4 kW |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

Product Features

1. Drilling Power Head

The drilling power head is equipped with a dedicated servo spindle motor, which adopts a toothed synchronous belt for speed reduction and torque enhancement to drive a specialized precision spindle. The spindle utilizes six rows of Japanese angular contact bearings (four at the front and two at the rear) and enables stepless speed regulation. A pneumatic tool change system is integrated into the spindle, ensuring more precise tool replacement that is both fast and convenient.

The feeding movement is driven by servo motors and ball screws. The X-axis and Y-axis support linkage and adopt semi-closed-loop control, enabling linear and circular interpolation functions. The spindle end is designed with a BT50 taper hole and fitted with a high-speed rotary joint, allowing for machining operations using a high-speed U-drilling center.

2. Transmission Device

The high-precision design of guide rails and sliders imported from Taiwan ensures smooth operation and effectively enhances heavy-load bearing capacity.

a. The X-axis and Z-axis each adopt two rolling linear guide rails, which serve as guiding and load-bearing rails for horizontal and vertical movements respectively. This configuration meets the technical requirements for high-speed drilling. For transmission, the X-axis and Z-axis utilize AC servo motors to drive precision ball screws for rotation, thereby achieving linear motion.

b. Two heavy-duty rolling linear guide rails are installed on each side of the Y-axis, with one of them featuring a side-mounted structure; together, they form the Y-axis sliding track. This setup not only satisfies the high rigidity and strength requirements of the gantry frame but also delivers technical advantages such as a low friction coefficient, high moving speed, excellent vibration absorption performance, and a long service life. The Y-axis transmission adopts dual-servo motor synchronous drive technology—specifically, one servo motor is arranged on each side, which synchronously drives the ball screws to rotate, further driving the gantry frame to move and enabling CNC machining operations.

The CNC gantry drilling and milling machine is a high-performance industrial device specifically engineered for the precision machining of plate-type components and structural parts. This equipment is tailored for processing workpieces such as flanges, discs, rings, and plates—with the core prerequisite that the thickness of these workpieces fully complies with the machine’s specified effective machining range.

In steel structure workshops, the equipment performs precise drilling and milling operations on structural plates and connectors, thus laying a solid foundation for the stable assembly of steel frames. For wind power applications, it conducts high-precision processing on wind turbine towers and flanges—a key requirement to ensure these components can withstand harsh operating conditions (e.g., strong winds, temperature fluctuations). In bridge construction projects, it undertakes the machining of bridge girders and brackets, guaranteeing stable and durable connections that are capable of bearing dynamic loads throughout the bridge’s long-term service life.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!